Can Linen Thread Be Dyed? A Simple Guide to Natural Fiber Dyeing

Learn how to dye linen thread at home and why pre-dyed premium thread from Hemptique might save you time and effort.

Innovation & Quality

Developing and supplying premium-quality, sustainably grown, consumer products

100% Natural

Organically Grown and Ethically Sourced

hemp and other natural fiber products

Shipping

We offer fast shipping

Your order out within 1-3 days

Wholesale

Visit our wholesale portal to register or login to your account

Linen thread is a staple in many crafts, valued for its natural strength, smooth texture and heritage appeal. Crafters often need their thread to match a specific project - be it bookbinding, leatherwork, textile repair or handmade accessories. That’s when the question arises: can linen thread be dyed?

The answer is yes, but with important caveats. Linen, made from flax fibers, accepts color fairly well using specific dye methods designed for natural fibers. However, not all linen threads are ready for dyeing, especially if it’s been waxed or treated.

Table of Contents:

What Kind of Dye Works Best on Linen Thread?

Step-by-Step: How to Dye Linen Thread at Home

Challenges of Dyeing Linen Thread at Home

Can You Dye Waxed Linen Thread?

Alternative: Save Time with Pre-Dyed Linen Thread

Matching Linen Thread Color to Project Materials

Final Words: Should You Dye Linen Thread or Buy It Pre-Colored?

Explore Hemptique Premium Linen Thread Collection

For those who prefer to focus on their craft instead of mixing mordants or stripping wax, Hemptique offers a professional-grade alternative. Our Linen Collection is made from long-staple Egyptian flax and lightly waxed for improved tension control, resistance to moisture and easier threading. The result is a dependable thread that performs well across a wide range of creative applications.

Our color options for linen cord, thread and yarn currently include natural (bleached), black, red, denim blue, brown and gold. Each shade is carefully selected to complement materials like leather, canvas and paper. The threads come in multiple thicknesses, offering flexibility for fine detail or heavy-duty seams. These are ready-to-use, cleanly spun, and designed to deliver consistent results without the challenges of DIY dyeing. Crafters who value quality, sustainability and ease of use will find Hemptique linen thread to be a dependable supply that saves time while enhancing the final look and longevity of their work.

More colors are on the way! Stay tuned as we expand the palette to include additional tones.

Our color options for linen cord, thread and yarn currently include natural (bleached), black, red, denim blue, brown and gold. Each shade is carefully selected to complement materials like leather, canvas and paper. The threads come in multiple thicknesses, offering flexibility for fine detail or heavy-duty seams. These are ready-to-use, cleanly spun, and designed to deliver consistent results without the challenges of DIY dyeing. Crafters who value quality, sustainability and ease of use will find Hemptique linen thread to be a dependable supply that saves time while enhancing the final look and longevity of their work.

More colors are on the way! Stay tuned as we expand the palette to include additional tones.

Can Linen Thread Be Dyed?

Yes, linen thread can be dyed because it’s made from flax, a natural cellulose-based fiber that accepts color well.

However, the success of your dyeing process depends on the type of thread you're working with, how it’s been treated, and the dyeing method used. For best results, the thread must be clean, unwaxed and scoured properly. Waxed linen thread blocks dye from penetrating the fiber, making it unsuitable unless the wax is removed first.

What Kind of Dye Works Best on Linen Thread?

The best results come from using dyes formulated for plant-based fibers. Below are the most effective options for dyeing linen thread:

Fiber-Reactive Dyes (e.g., Procion MX)

- Permanently bonds with flax fibers, producing strong, vivid colors that resists washing and fading.

- Ideal for when you need reliable color on exposed thread, such as visible leather stitching or accent seams in linen upholstery.

- Requires pre-treatment with soda ash and a warm water bath to activate the dye bond.

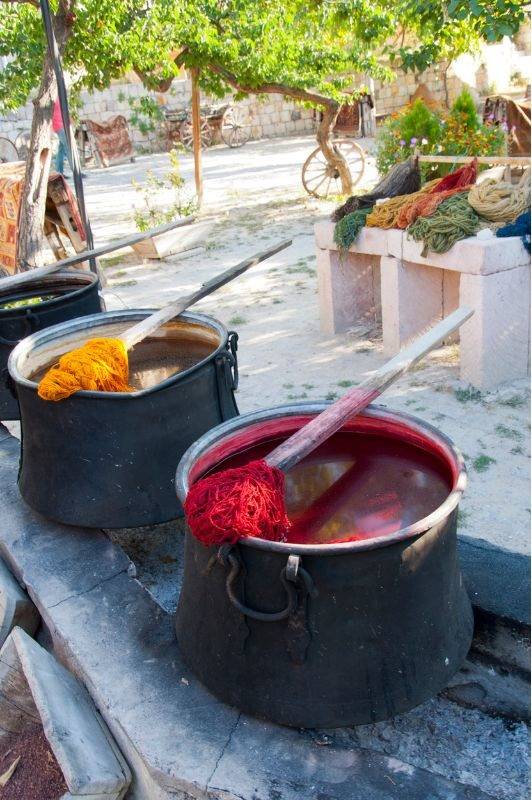

Natural Dyes (e.g., indigo, madder, onion skins)

- Produces subtle, botanical shades. Great for projects requiring a more natural or aged look.

- Works best when thread is mordanted with alum or tannin for colorfastness.

- Often used in slow crafts like hand-bound journals, botanical art pieces or eco-dyed fiber kits.

Some natural dyes are sensitive to pH levels, meaning their color can shift depending on the acidity or alkalinity of the dye bath. For example, hibiscus may dye a pinkish red in acidic water but turn purple in alkaline conditions. Always test small samples before committing to a full spool.

Not Recommended: Acid Dyes

- Designed for protein fibers like silk or wool. Will not bond properly with flax.

- Using these on linen results in washed-out color and poor adhesion.

Traditional Dye Pots for Thread & Yarn Dyeing

Step-by-Step: How to Dye Linen Thread at Home

Dyeing linen thread at home is possible with a bit of patience and planning. Below is a simplified process for small-batch, fiber-reactive or natural dyeing:

1. Clean and Prep the Threadading text goes here

- Soak the thread in warm water with mild soap to remove oils, sizing or wax (if present).

- If using waxed thread, repeat the soak and rub gently to strip wax completely.

- Hang to dry on a rod or wooden rack. Avoid dryers or plastic surfaces that may reintroduce static or residue.

2. Pre-Mordant (for Natural Dyes Only)

Always mordant in a well-ventilated space. While alum and tannin are commonly used, they can produce fumes when heated, especially in enclosed areas. Use gloves and avoid inhaling vapors if using warm or hot mordant baths.

- Dissolve alum or tannin in warm water and soak the thread for several hours or overnight.

- Rinse lightly before adding to dye bath.

3. Prepare the Dye Bath

- Follow manufacturer directions for fiber-reactive dye or simmer botanical material in water for natural dyes.

- Strain to remove plant matter if needed.

4. Submerge the Thread

- Lower the thread into the bath gently, stirring occasionally for even coverage.

- Let it sit for 30–60 minutes. Longer times deepen saturation but may also increase stiffness if not rinsed properly.

5. Rinse and Dry

- Rinse thread in cool water until the water runs clear.

- Air-dry in a shaded area. Avoid hanging near heat sources which may cause color shift or uneven tension in the fibers.

- Even when using fiber-reactive dyes, proper rinsing is critical. If excess dye isn’t fully washed out after the dye bath, it can transfer onto fabric or hands during use. Rinse thoroughly until the water runs clear and allow the thread to air dry in a shaded area.

Optional: Once dry, re-wax the thread if you're using it for leather stitching or bookbinding.

Challenges of Dyeing Linen Thread at Home

Many crafters find that home dyeing introduces complications that impact their workflow or final product quality. Below are the most common issues, especially for those using dyed thread in functional or archival work:

Wax Interference

- Waxed thread repels dye, leading to patchy, uneven coloration.

- Removing wax can be time-consuming and may weaken the thread if over-scrubbed.

Inconsistent Color Absorption

- Even small differences in thread tension or twist can result in streaks or blotches.

- Threads dyed in small home batches rarely match exactly, making it hard to replicate color across multiple projects.

Risk of Bleeding or Transfer

- Inadequately rinsed thread can stain adjacent materials, especially in humid climates or when used in contact with light-colored fabric or paper.

Color Fade Over Time

- Natural dyes are prone to fading unless properly mordanted and stored.

- Even fiber-reactive dyes may dull over time with sun or moisture exposure.

Additional Equipment and Prep

Successful dyeing requires fixatives, gloves, pH-controlled baths and ventilation - often more than a casual hobbyist wants to manage.

Can You Dye Waxed Linen Thread?

Waxed linen thread is coated with a layer of beeswax or soy wax that creates a protective barrier. This wax prevents dye from penetrating the flax fibers evenly, often resulting in streaked, blotchy, or completely color-resistant areas. Even if you try to remove the wax, it’s rarely 100% effective, and residue can linger.

- Soak the thread in hot (but not boiling) water mixed with mild detergent.

- Gently rub it with a soft cloth to lift the wax, without damaging the thread twist.

- Rinse and hang to dry completely before dyeing.

This multi-step process often degrades the thread's strength or leaves patches of wax behind, which still resist dye. For projects which require precise color or durability, like saddle stitching, spine sewing or exposed embroidery - it’s not worth the risk.

Alternative: Save Time with Pre-Dyed Linen Thread

Home dyeing is an option, but for many crafters, the trade-offs aren't worth it. The time spent stripping, mordanting, testing, rinsing, drying and possibly rewaxing adds hours to what should be the creative part of your project. Inconsistent color, wasted materials and the cost of dyeing supplies often outweigh the savings.

- Each spool is made from 100% Egyptian flax and comes in smooth, consistent plies.

- Threads are lightly waxed and ready for immediate use in hand-sewing, stitching, upholstery, bookbinding, jewelry making and more.

- Available colors include Natural, Black, Red, Denim Blue, Brown, and Gold - with more shades in development based on customer feedback and popular design trends.

Instead of spending your afternoon testing dye ratios, you can spend it crafting with color you can trust. The finish is clean, the thread holds tension beautifully and the results are always project-ready.

Matching Linen Thread Color to Project Materials

One of the most common goals behind dyeing linen thread is to match it to leather, fabric or paper. While this sounds straightforward, achieving a precise match is rarely simple when working with flax-based fibers.

Linen thread absorbs dye in unique ways depending on several factors. The thread's twist, tightness, and any residue or leftover wax can affect how color settles into the surface. Even two spools from the same batch can show slightly different results when dyed under the same conditions.

Natural dyes especially tend to produce unpredictable shades. Plant-based ingredients like onion skin, walnut or indigo react to water pH, mordant strength, and steeping time. This often leads to variations in hue and saturation - even when using the same recipe.

Color fastness is another concern. Some naturally dyed threads fade more quickly when exposed to sunlight or moisture. Over time, a once-matched thread can look noticeably different from the surrounding materials.

Even with fiber-reactive dyes, matching thread to a specific shade of leather or fabric is tricky. Dye tests are helpful, but they rarely guarantee perfect consistency across multiple skeins or between batches.

If a project requires visible stitching, restoration work or tight color coordination, be prepared for trial and error. For some crafters, the process of experimenting is part of the creative reward. For others, it may not be worth the unpredictability.

Final Words: Should You Dye Linen Thread or Buy It Pre-Colored?

Dyeing linen thread at home can be a rewarding experience - for hobbyists with time, tools and a willingness to experiment. It’s a useful way to explore natural color processes and engage deeply with your materials. But for most crafters, the drawbacks become apparent quickly: wax interference, uneven dye take-up and color unpredictability often compromise the result.

This is especially problematic when you're working on commissions, restorations or time-sensitive projects where quality control matters. The wrong color, a streaked result or degraded thread integrity can undo hours of work.

That’s why many professionals turn to Hemptique’s premium dyed linen thread, which is spun, waxed and finished for ready-to-use performance. You get color consistency, clean plies and dependable durability without needing soda ash, mordants or wax blocks.

Learn More in the Hemptique Knowledge Base

Crafting with natural materials requires the right supplies, plus knowledge insight, and a clear understanding of how to work with flax, hemp, cotton and other plant-based fibers. That’s why Hemptique has created a growing Knowledge Base, a free resource designed for crafters, artisans and DIYers who want to get the most from their materials.

Frequently Asked Questions

Can I dye linen thread using food coloring or RIT dye from the grocery store?

No. Food coloring is not suitable for plant-based fibers and RIT dye blends are often not strong enough to bond with flax. For true results on linen thread, use fiber-reactive dyes or well-prepared natural dyes with mordants.

Why did my dyed thread fade after a few weeks, even when I followed instructions?

This often happens when mordants weren’t strong enough or when natural dyes were exposed to direct sunlight. Flax fibers also swell and shrink with humidity, which can subtly affect the surface color. Store dyed threads in shaded, stable environments to reduce fading.

Can I re-dye a thread if the color didn’t turn out right?

You can try, but multiple dye baths may overwork the thread, causing stiffness, shedding or loss of tensile strength. Always test on small scraps first and avoid layering strong colors over each other.

What’s the safest way to remove wax from linen thread before dyeing?

Soak it in warm water with mild soap (not detergent) and gently rub between clean cotton cloths. Avoid hot water or boiling, which may alter the fiber twist. Expect the thread to lose some of its structure and feel.

Can I match the color of my dyed thread to fabric or leather?

You can get close, but exact matches are difficult due to the way flax absorbs color. If your project depends on a perfect match, buying pre-dyed thread is a safer route.

Is there a difference in dyeing results between 12/3 and 18/3 linen thread?

Yes. Thicker thread like 12/3 takes longer to saturate and may show slight interior fade if not fully immersed. 18/3 accepts dye more evenly but may appear lighter due to finer fiber surface area. Always test each size separately before committing to a full dye bath.