Hemptique

Products Of Earth

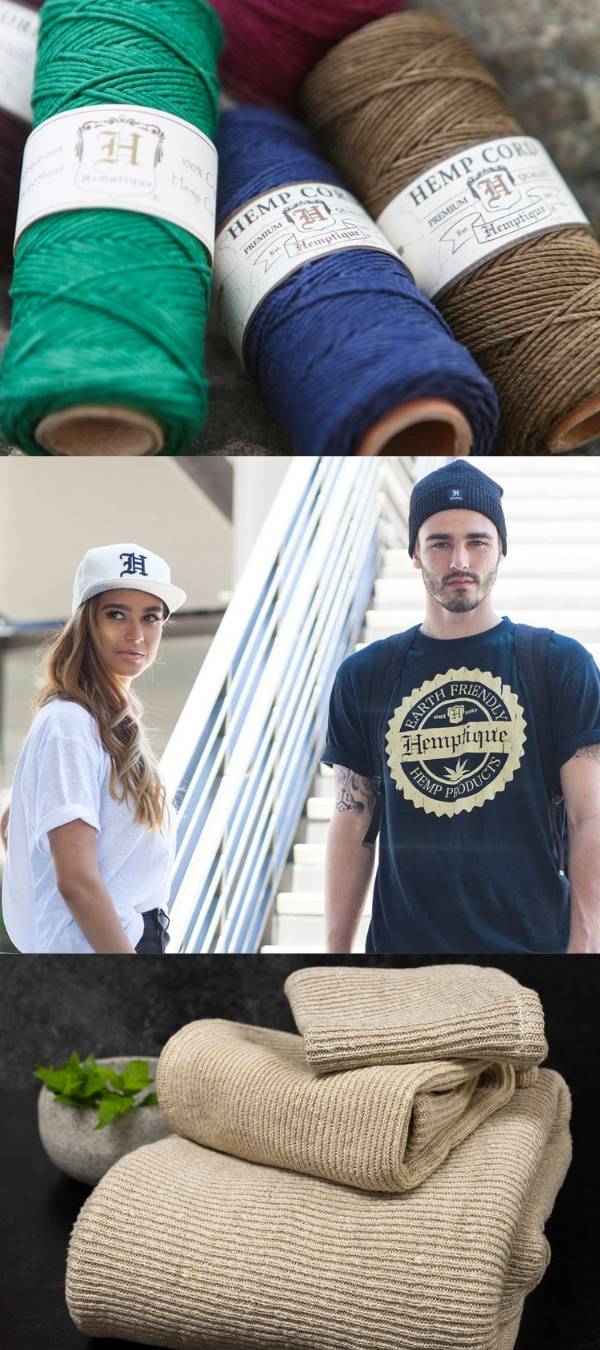

Hemp has always been a part of Peter Nyari's culture and upbringing. He was raised in Hungary, where his family has used hemp for generations. "This plant can provide you with shelter, clothing and a multitude of other uses," he says. Noticing that industrial hemp-based products were missing from the marketplace, he realized there was an opportunity to grow a business while making a positive difference. Through his company, Hemptique, Peter and his team bring hemp cordage, craft threads, ropes and fabrics to consumers.

"Our philosophy is that well-made and long-lasting natural products contribute to optimal environmental and personal health, as well as quality and sustainability."

"Act local, think global" is Hemptique's purpose in action. Peter explains: "It keeps us aligned with our primary goal of continually providing the best eco-friendly and sustainable products while enabling us to maintain our learning and adapting mindset. The Hemptique team closely collaborates with an ever-increasing group of like-minded people. We strive to educate people about the awesome uses of hemp, and how it can provide them and their environment with healthy solutions. We show people that there are healthy and sustainable alternatives that can help them to reduce and eliminate their dependence on synthetic items. When you introduce hemp into your daily life, you are enriching and nourishing your body and your surroundings. You are creating a healthier world for future generations as well."

Hemp is a quick-growing crop, generally taking 110 days to mature. "After harvesting, retting and drying of the hemp stalks, the process of turning hemp into a finished product continues with decorticating, scutching, hackling, roving, combing and spinning the goldish/blond fine fiber into fine hemp yarn to be made into a multitude of high-quality, human- and planet-friendly finished products."

Their materials originate from Europe and Asia. "From our office in Southern California, we coordinate our global network of product development and product fulfillment activities," says Peter. "With our international flair and expertise, Hemptique is an innovative, zero or minimal carbon footprint-focused leader; one that focuses on craft and lifestyle products made from hemp, organic and recycled natural fibers."

The creative team in California designs products and innovative uses for the Hemptique offerings. "Our lifestyle and craft products have been expanded to in- clude fun and trend-setting products which include macramé and themed magical color combinations and much more. Hemptique prides itself on designing developing and supplying trendy, fashionable and functional products that are environmentally sustainable and socially responsible."

FIBER TYPES

The image above shows a hemp stem. The outer material contains the prized bast fibers and the inner is the hurd, which is made up of short fibers. The short fibers produced during the separation process are known as "tow" and the long fibers are called "line fibers." Line fiber can be incredibly long-depending on the height of the plant, a single strand may be up to five meters in length. Once separated, the line fiber is cleaned and carded to size, cut and baled, ready to be further processed and spun. The tow fiber is just compressed and baled.

GROWING HEMP

Our hemp fiber supply model follows a traditional method of hemp textile production.

CULTIVATION

Seeds are sown densely to produce tall, slender stems that contain a greater amount of fine fibers.

HARVESTING

Takes place after flowering but before the seeds are set, as fibers tend to become coarser around the time of seed formation.

RETTING

Takes place after flowering but before the seeds are set, as fibers tend to become coarser around the time of seed formation.

WATER RETTING

Involves soaking the stems in water tanks, ponds or streams for around seven to ten days. Warmed water laden with bacteria is most effective.

DEW RETTING

Entails laying the crop on the ground for three to six weeks. turning the plants occasionally to allow for even retting.

FIBER SEPARATION

BREAKING

Stalks are passed between fluted rollers to crush and break the hurd into small pieces, separating some of the fiber in the process. Though once a very involved and labor-intensive process, separation of the best from the hurd has been somewhat simplified through the use of a machine called a decorticator, which enables the leaves to be left on the stalks during the breaking, although this makes for a messier process requiring more sorting after completion.

SCUTCHING

The broken stems are then beaten and scraped, sepa- rating more short fiber and the remaining hurd material from the long fibre.

REFINEMENT

HACKLING

The fibers are then hackled (combed) to remove any remaining woody particles and to further align the fibers into a continuous sliver.

ROVING

This sliver is twisted and drawn out further to improve strength, then wound on spinning bobbins.

SPINNING

Generally, to produce a better, finer yarn, the fibers are then thoroughly wetted in a small trough of water as part of the spinning process. known as wet spinning. Fibers can also be dry spun. which often results in a coarser yarn.